What Are Shell Casings Made Of?

One of the significant components in any rifle, including machine guns, is the shell casing. A shell casing serves as a house for the different parts of the artillery ammunition.

Proper knowledge of the shell casing and the different materials that make up the shell casing is essential for any shooter.

This article will shed light on ammunition casings; we will also help you answer the question “What are shell casings made of?”. The uses of the materials; the pros of brass, Steel, Nickel, and aluminum casings, and when to choose them.

Let’s get into it.

What Are Cartridges Made From?

We understand that it is crucial to know how a gun works.

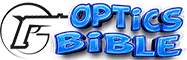

A complete round of artillery ammunition has four parts: the case, the primer, the powder, and the bullet.

Case

A cartridge casing houses all the other parts. The pistol or rifle case can be Brass, steel, or copper. Plastics are also used, but a thin layer of Brass covers the bottom.

The primer

The primer is located at the bottom of the cartridge. When the firing pin hits the primer, an explosion sets the gunpowder on fire. The eruption starts a fire that spreads through the shell and lights the powder.

Powder

Gunpowder, also called propellant, is a material inside the cartridge case that burns quickly. Both chemical explosives and black powder or smokeless powder can be used as Propellant. The propellant burns so quickly that it makes a gas that increases the pressure inside a cartridge.

It is packed into a shell casing or a combustible bag. Depending on how the propellant is loaded into the gun with the bullet. Artillery ammunition is classified into three groups: fixed, semi-fixed, and separated.

- A fixed round of ammunition contains a shell casing fixed to the projectile.

- With semifixed ammunition, the casing and the projectile still fit together, but the shell casing can be removed to adjust the size of the powder charge.

- Separated ammunition – the shell casing is not attached to the projectile with separated ammunition. Typically, the shell casing for the separated bullet is closed with a plug to protect the Propellant and assist with pushing the shot into the gun’s chamber.

The bullet is a cylinder-shaped, pointed projectile from the barrel. It is usually made of metal that contains lead. When the gunpowder is lit, gas builds up inside the cartridge, which enables it to fire bullets. Some bullets are made from lead, while others are made from copper. A shell can also have a lead core with a copper coating.

Nickel-Plated Casings

Nickel-plated casings have, over the years, become the best alternatives to brass-plated casings. This is due to its nice and appealing nature compared to the brass casings. Let’s consider some of its benefits.

Benefits of Nickel-Plated Casings

Easy loading: Nickel-plated brass has a lower coefficient of friction than just Brass. The low coefficient of friction also allows for smoother and easier extraction of nickel-plated cases.

Nickel-plated Brass is corrosion resistant

This makes the Nickel-plated casings a great option among law enforcement officers. Nickel-plated casings are vergridis resistant. The green spots that show up on old Brass due to the storage.

Nickle-plated brass casings can be handled consistently or stored on a leather gun belt for extended periods and show zero tarnish.

The aesthetic appearance

Many armed professionals and concealed firearms carriers find the nickel-plated brass cases easier to see when checking the chamber to ensure their firearms are loaded.

Improved strength

The nickel casing strengthens the case’s material, making it last longer.

Nickel coatings are known to have an influence on fatigue strength, corrosion fatigue, galling, and fretting corrosion. Coatings of nickel on steels having a tensile strength greater than ca. 420 MN mm−2 are significant in reducing fatigue strengths.

Ease of cleaning

nickel cases are easier to clean than other metals. During cleaning, brass cases typically require a polish added to the tumbling media to remove any tarnish. However, a quick clean in the tumbler with untreated media for nickel cases should be enough to clean off any dirt, unburnt powder, or debris in the cases to make them look brand new.

When to Choose Nickel-Plated Ammo Casings

Nickel-plated cases are often leveraged for hunting and defensive ammo. Since Nickel cases have a higher corrosion resistance than brass ones, they are better suited for leather holders. The brass casing can stain the leather, creating unsightly marks.

The nickel plating is visible in dark or low-light conditions; this makes it easier when checking if the rifle is loaded or not.

Brass Casings

Brass casings have been around for the longest time possible. They are generally preferred compared to steel or aluminum casing. Some of their advantages include the following:

Benefits of the Brass shell casing

Reusability

The brass casings can be used and reused severally. This enables you to save on costs.

Brass metal has a lower failure rate

Brass is a relatively soft metal, which works in its favor when used as a casing. It’s easy to spot an issue with a brass case because of the softness of the metal. You can see if it’s deformed or misshapen.

Doesn’t scratch

Another benefit of the softness of Brass is that it’s less likely to scratch your firearm or otherwise mar or damage it.

Brass is more malleable, so the case seals better in the chamber (it expands) when fired. This gives more consistency in long-range shooting and keeps your weapon cleaner. It can also be reloaded.

Less costly compared to the Nickel casing. Brass cases are cheaper compared to Nickel casings.

This is due to the easy availability of materials. Although steel cases are the least expensive of the three, brass cases are a good compromise, and there are numerous sources of once-fired Brass for handloading.

Reliability

Brass cases are known for their extreme reliability under extreme weather and temperature conditions.

Brass-cased ammunition is also of generally higher quality than steel-cased ammo. It is manufactured according to tight specifications. This promotes greater functionality in firearms that are designed to feed, fire, and extract ammo.

This reliability of brass is enhanced by the softness of brass which tends to show deformation when overpressured or worn out.

When to Choose Brass Ammo Casings

Brass ammunition casings are the preferable shell casings compared to other metals. For any long-range shooter, the brass casings are the ideal choice. This is due to their consistency.

Furthermore, even though they are costly compared to steel or some of the different metals, they will provide you value in the long run since they are easily reloaded and work reliably in different environments.

Steel Ammo Casings

Brass and steel are the most popular metals used to make shot casings.

New shooters are likely to appreciate that steel-cased ammo costs less than steel-cased ammunition, which often has a polymer exterior coating. To reduce friction and enhance cycling.

Steel casing can be handy by providing an affordable option for many firearms owners. However, you must be aware of the potential drawbacks and compare these to typical brass cases.

Benefits of Steel Casings

Cost

The iron needed to forge steel comprises 6.3% of the earth’s crust. That means it is over 900 times more abundant than the copper requisite for making Brass. This makes the steel casing very cheap.

Tougher Cartridges

Steel is a more rigid metal than Brass; the hardened steel cases are less likely to be damaged and misshapen.

Magnetic properties

The steel cases used in guns are magnetic, making picking up spent cases easier, especially for people with bad backs. A telescoping magnet will make the work easier for you.

Versatile Steel-cased cartridges are coated in lacquer or polymer, which makes them resistant to rust and offers more corrosion resistance. This makes steel case ammo ideal for long-term storage.

When to Choose Steel Ammo Casings?

While steel cases have cons compared to other casings, they can be affordable for high-volume target shooters who want a low-cost alternative. With steel cases, you can enjoy your favorite shooting sport with less burden on your wallet.

The steel casing is an excellent choice for people who don’t reload. And it’s much faster to pick up and throw away because you can use a roofing magnet to capture it.

Aluminum Ammo Casings

Aluminum is one of the best options for your casings. Aluminum cases have been on the market since the early 1980s. This provides shooters with an alternative option to brass or steel cases.

Let us consider some of the benefits.

Benefits of Aluminum Casings

Corrosion resistance

Aluminum is less corrosive compared to steel. Aluminum is able to resist corrosion even when exposed to air and water. It naturally generates a protective thin oxide coating which keeps the casing from making further contact with the environment thus reducing rust and corrosion.

Easily visible

Aluminum is a good reflector of visible light. It has a high light reflectivity of over 80% (including radiated heat such as sunlight which makes the casing easily visible.

Improved strength

Compared to steel casings, which rapidly become brittle at low temperatures, aluminum shows increased tensile strength as temperatures drop.

Cost

compared to brass or nickel-plated casings. This is due to the lower manufacturing costs, which lower the sticker price.

Weight

Aluminum is a very lightweight metal. This makes it an ideal option for range shooters who walk long distances.

Easy to clean

The smooth surface of the aluminum casing is very easy to keep clean, this ensures that they do not retain odours from the environment which will therefore keep your casings clean.

When to Choose Aluminum Ammo Casings?

Aluminum ammo is an excellent option if you are looking for cheap practice rounds.

However, reloaders and shooters using reloaded ammo should exercise caution around aluminum cases due to aluminum’s relative brittleness.

What Are Shell Casings Made of – FAQ

What Is A Bullet Casing?

The Bullet casing is the house that holds together the primer, the Propellant, and the bullet. The case also protects the powder and primer from moisture and contamination.

What is the Difference Between A Shell and A Casing?

The shell is the housing used to oblige the propulsive material. It contains the primer and propellant powder to discharge the bullet or projectile.

While the casing is cylindrical, usually metal, capable of being loaded with an explosive charge and a bullet, the shot casings typically have a plastic sleeve that holds the shot attached.

Do All Guns Leave Shell Casings?

No, a few guns will leave signs of shell housings once you fire the weapon.

Some firearms don’t abandon the casing. The pistol leaves the shell packaging once you shoot the projectile. The shell packaging is set inside the chamber when you discharge the gun. It is generally found in Colt Python revolvers.

Can You Trace Shell Casings?

No. In most cases, the process of tracing shell casings is usually tedious and expensive. A fired bullet can often be matched to the barrel. But Rarely traced back to it Unless the ballistics are on file.

Some bullets are designed to flatten or break apart, which makes matching the rifle to the barrel challenges.

What Happens To Spent Shell Casings?

Since the world war, casings from ammunition fired at the gun range in training are collected and then sold like any other military surplus. They can be sold as reloading components, or they can be sold as scrap.

For the U.S. military, the Brass is picked up. This is done to keep the range clean and for accountability. A certain percentage of the fired Brass must be turned in to prove the ammunition was fired and not stolen. Brass on the battlefield is left there.

What kind of Brass are shell casing made from?

Cartridge brass or the c260 brass is the most common type of Brass used for the shell casings. It contains a copper alloy with about 30% zinc by weight, is easy to produce, and is often cost-effective because zinc generally costs less than copper.

This most popular Brass has attractive properties for the cartridges, which include an excellent combination of strength, flexibility, and conductivity.

Are bullet casings pure brass?

No. Brass is a mixture of 70% copper and 30% zinc. Bullets can also be solid bronze which may contain copper and tin. Solid zinc alloy is also used for bullet casings.

Are bullet casings made out of copper?

Copper hasn’t been used for casings since the 1800s because it is a poor metal. It is too soft to handle the pressure of smokeless powders and doesn’t spring back, leading to stuck cases.

What are bullet shell casings?

A bullet Shell casing is the part of handgun ammunition that contains the primer and powder to fire the projectile.

When the charge is ignited, the casing expands slightly and seals the chamber like a gasket; this makes loading practical.

How much are brass shell casings worth?

The value of Brass depends on its quality. The quality is basically how safe it is to reload it repeatedly until it is not safe to fire. It is good to consider how often the brass casing has been fired before buying it.

The scrap value for brass shell casings may vary depending on the area. However, you can get more from reloaders if you sort the shells by caliber and visit a local gun show.

Are brass casings better than steel?

Yes, Even though steel is cheaper than Brass, Brass stands out as the better option.

This is because better brass casings are easier to reload and less likely to damage the firearm’s chamber. They are more pliable, which leads them to provide a better seal in the chamber when fired.

Brass is somewhat springy—that is when fired, it expands to fill the chamber and provide obturation, but as soon as the bullet leaves the bore, pressure drops, and the brass case will shrink back somewhat, allowing for easier extraction.

Do steel casings hurt your gun?

Yes, it may hurt your gun.

After firing, the steel shell tends to get stuck in the ejector, which you must clear before you can fire again. The steel case is more complex than brass, so it gets stuck instead of slightly deforming the ejector and clearing the port.

Conclusion

Getting the best casing for your gun was the article’s primary goal.

We have educated you on the different materials used for the shell casing: Brass, Nickel, Aluminium, and steel. We have also labored to highlight the benefits of each material.

Now it is our turn to hear from you. Which shell casing did you prefer?

Feel free to comment below and also share the post with your friends.