Parkerized vs Nitride: Exploring 4 Parameters To Find the Winner

Are you unable to choose between Parkerized vs Nitride as the ideal gun finish? Worry not, as we’ve got you covered. Today, we will take an in-depth look into these finishes based on four crucial parameters and discuss the pros and cons.

We won’t stop here but will also examine their durability to help you make an informed decision. So, if you’re seeking clarity on which gun finish reigns supreme, keep reading!

Waterproofing Properties of Gun Finishes – Enhanced Corrosion Resistance

Gun finishes possess inherent waterproofing properties. They establish a robust barrier between the firearm’s surface and environmental elements like moisture, etc. During the manufacturing process:

- Meticulous attention is given to ensure the gun’s surface is thoroughly cleaned.

- It helps to prevent the entrapment of moisture or air.

There are some weaker gun finishes like blueing or anodizing exhibit reduced waterproofing capabilities. So, you get corrosion in a few years. But the advancements in finish technologies like Diamond-Like Carbon and Hybrid coatings have significantly improved longevity and protection. With modern tech, it is possible for a gun to maintain its waterproofing integrity throughout its entire lifespan.

A Quick Sneak Peek Into Parkerized vs Nitride

When comparing gun finishes, it’s essential to consider their unique characteristics and implications.

Parkerizing

Parkerizing is a corrosion protection process.

- It involves applying a thin layer of zinc or manganese to enhance corrosion resistance.

- This durable finish is commonly used on firearms.

- But it does pose challenges when you want to change the gun’s color in the future.

Nitriding

Nitriding is a surface-hardening process.

- It enhances the metal’s hardness without affecting its dimensional accuracy.

- In this process, nitrogen is diffused into the metal’s surface.

- It improves the resistance to wear and tear.

- You should also note that Nitriding can increase brittleness which can potentially lead to breakage.

There’s even more to learn beyond these key points, so keep reading for a comprehensive analysis!

Choosing the Optimal Firearm Coating

When it comes to firearm coatings, there are several different types available. Each has its own unique properties and advantages. To determine the best coating for your firearm, it is essential to understand the options at hand:

Coating | Durability | Attractiveness | Learning Process (We have scored all of them from 1-10) |

Gun Bluing: | 7 | 10 | 3 |

Parkerizing: | 9 | 8 | 8 |

Anodizing: | 9 | 8 | 10 |

Cerakote: | 9 | 8 | 10 |

Duracoat: | 9 | 8 | 1 |

Nickel Boron: | 9 | 8 | 10 |

Chroming: | 9 | 10 | 8 |

Quench Polish: | 9 | 8 | 10 |

Hydrodipping & Skinning: | 5 | 8 | 1 |

Powder Coating: | 2 | 5 | 8 |

What is Parkerizing? Detailed Overview

Parkerizing is a technique comparable to bluing. It offers a similar level of durability. But, it is a more complex process to undertake independently. However, parkerizing yields a moderately attractive finish that enhances the natural color of the underlying metal on the gun.

This type of coating is frequently utilized by military forces for their weapons and equipment. Let’s take a detailed look!

Durability

It is a really good finishing technique that offers long-time durability.

- With proper maintenance, a Parkerized finish can withstand heavy use and exposure to various environmental conditions.

- It is worth noting that the durability of Parkerizing can vary depending on the specific application and the level of care provided.

- Regular cleaning, lubrication, and protection from moisture are essential to maintain the durability of the Parkerized finish over time.

- You have control over the application of the finish.

- It is a DIY-friendly process so you shouldn’t face any problems.

- The finish is visually appealing and enhances the overall look.

- The ability to apply oil allows for absorption and provides added protection.

- Parkerizing is a slightly costlier method and demands more equipment.

- This procedure takes a considerable amount of time to complete.

Parkerizing Procedure

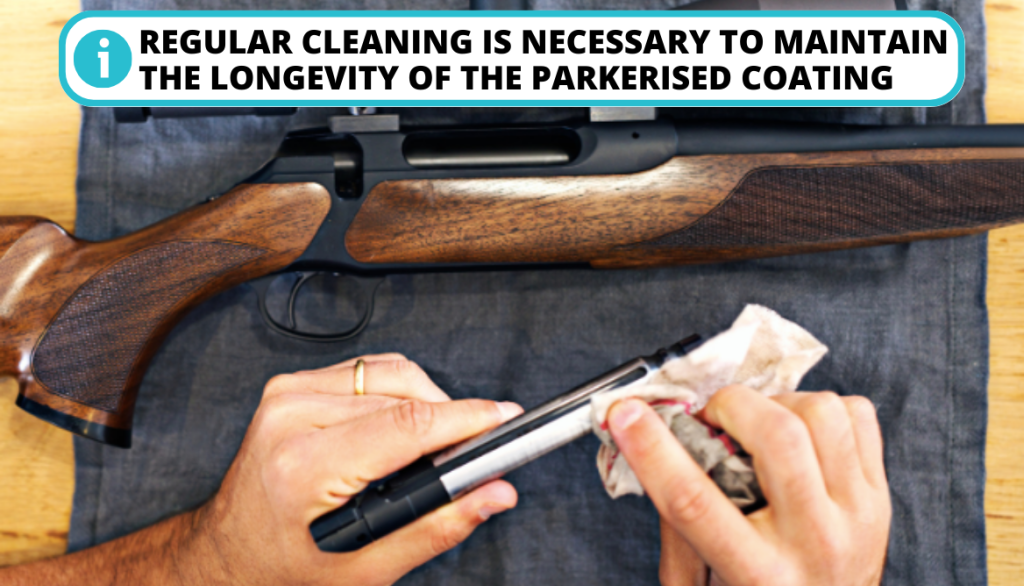

If you are looking for the procedure, here is a step-by-step guide:

- Take a rag and degrease the stainless steel tank, thoroughly wiping the entire interior, including the lid.

- Add a mixture of 1 part Manganese Phosphate to 4 parts Water to the tank, filling it until it is nearly full.

- Ignite the burner and heat the tank, ensuring the solution reaches the desired temperature of about 190-210 °F.

- Using a metal holder, suspend the gun part in the tank solution, allowing it to immerse for a period of 5 to 10 minutes.

- After the designated time has elapsed, remove the gun part from the tank and rinse it off thoroughly with water.

For more information, you can check out this short video.

What is Nitride Coating? Detailed Overview

It is a surface treatment process applied to metal components to enhance their durability and rust resistance. The metal component is placed in a controlled environment with a nitrogen-rich atmosphere.

Through a thermochemical reaction, the nitrogen atoms penetrate the surface. It forms a hard nitride layer that becomes an integral part of the metal structure. Let’s discuss this process in detail!

Durability

Nitrided barrels are highly regarded for their exceptional durability. The coating significantly increases the hardness of the barrel.

- It makes it more resistant to wear and corrosion.

- This enhanced durability ensures that the barrel can withstand the rigors of continuous use.

- Nitrided barrels have longer lifespans compared to barrels with traditional finishes.

- The hardness of a nitride barrel also contributes to improved accuracy.

- Nitride finish offers exceptional hardness.

- Increased strength of the metal contributes to longer nitride barrel life and enhanced protection.

- It exhibits high resistance to erosion improving the barrel life of the rifle.

- Nitride barrels perform well in extreme temperature conditions.

- Nitride finish offers a really shiny look which some people might not prefer.

- The cost of applying a nitride finish is also higher compared to some other coating options.

Nitriding Procedure Explained in Detail

Here are a few easy steps for nitriding your rifle:

- The process begins with a salt bath nitrocarburizing cycle.

- You need to use a salt bath like Tenifer or Melonite.

- The temperatures should range from 1000℉ to 1600℉.

- Then the piece undergoes different polishing methods such as vibratory finishing and lapping.

- The final step is to immerse the piece in a hot potassium nitrate bath.

This is a good video showing you the difference between nitrided and chrome-lined barrels.

Most Durable Gun Finishes for Long-Lasting Performance

Durability is a critical factor to consider when selecting a gun finish. While various finishes are available, their durability can vary significantly. Let’s examine some of the most robust gun finishes on the market:

1. Cerakote

Cerakote, a ceramic-based coating, stands out as one of the most durable gun finishes. It is particularly good for its excellent wear and tear resistance. Its robust nature makes it an ideal choice for firearms subjected to heavy use.

2. Anodized Aluminum

Anodized aluminum emerges as yet another durable option. It is an excellent choice for individuals seeking a long-lasting gun finish. It helps in maintaining an attractive appearance over extended periods.

3. Stainless Steel

Steel is known for its excellent durability. It offers a robust gun finish that effectively resists corrosion and scratching. This makes it an optimal selection that will maintain the barrel’s appearance and help it withstand the test of time.

Final Thoughts

Both finishes have their respective pros and cons. But, Nitride emerges as the superior option overall.

- Nitride finishes offer exceptional durability.

- The hardness of Nitrided barrels contributes to longer barrel life and improved performance.

- Nitrided barrels have high resistance to erosion.

- The smooth surface of Nitride coatings simplifies the cleaning process and reduces the need for excessive lubrication.

However, Parkerizing finish has its perks too:

- It provides a moderately attractive finish that is not very shiny.

- Parkerizing is also a viable choice for those seeking a durable coating.

FAQ

What is a phosphate barrel?

Phosphate barrels refer to firearms that have undergone a zinc phosphate finish. It is a surface treatment process that enhances durability and corrosion resistance by creating a coating on the metal surface.

What is a nitrided barrel?

Nitrided barrel is a surface treatment process where nitrogen is diffused into the metal. Many gun enthusiasts prefer nitride finishes for their enhanced durability and performance.

Why are nitrided barrels more accurate?

Nitrided barrels tend to be more accurate due to the salt bath nitrocarburizing process. It improves the surface hardness and uniformity of the barrel.

Is nitride better than phosphate barrel?

Nitride barrels, produced through gas nitriding, are generally considered better than phosphate barrels. It is due to their increased hardness, improved rust resistance, and enhanced durability. You also get better accuracy with a nitride barrel.

Is chrome-lined barrel better than nitride?

A Chrome-lined barrel is advantageous compared to a nitride one due to its superior rust resistance and increased longevity. Chrome lining is really desirable for firearms.

Can a nitride barrel be chrome lined?

No, a nitride barrel cannot be chrome lined as the nitride process alters the surface of the metal. Thus, it makes it incompatible with the chrome lining process.

What’s the difference between phosphate and nitride?

The difference between phosphate and nitride finishes lies in the coating process. Phosphate involves the application of a chemical coating. While gas nitriding modifies the metal’s surface by diffusing nitrogen.

Are Parkerized barrels the same as phosphate?

Yes, Parkerized barrels and phosphate barrels are essentially the same. Parkerizing is a specific method of phosphate coating. It creates a protective layer on the metal surface to enhance durability.

Conclusion

So, if you are looking for the more superior finish then Nitriding is the way to go. It offers better longevity and also helps in maintaining barrel accuracy. If you want a uniform and more muted finish, then parkerizing is for you.

Ultimately, the choice between these finishes depends on individual preferences, specific use cases, and the desired balance between aesthetics and performance

So, which barrel finish are you going to use on your gun? Let us know in the comments!