Can You Mount a Scope without a Torque Wrench: Top-7 Recommendations

Can you mount a scope without a torque wrench? No! This is because not using a torque wrench means that the screws may not be tightened to the correct level, resulting in the scope becoming loose and misaligned.

In this article, we have discussed the importance of torque, the working of scope torque wrench, and the 7 best products for scope mounting. Let’s dive into the details!

Proper Torque Specs for Scope Rings

The proper specs for scope rings vary depending on the type of scope, mounting system, and firearm being used. It is best to consult with the manufacturer’s instructions for exact torque specifications. Generally, the torque should be between 17-20 inch-lbs.

Understanding Torque

Torque is a rotational force applied to an object to cause a change in its angular momentum. It is usually measured in units of inch-lbs or foot-pounds and is essential for tightening screws and nuts so that they do not become loose or wobble.

Why is Torque Important to Scope Rings?

Torque is important to new scope rings because it ensures that they are securely mounted and won’t move. Properly torqued scope rings also enable consistent long-range shooting results, making them essential for precision accuracy.

1. Do Not Use Any Kind of Thread Locker

Use of a low-quality scope ring may cause problems such as distortions, alignment issues, and even movement of scope out of the assembly fitting due to weapon recoil.

You will be able to avoid any inconvenience and major mishaps by following the precautions:

- Always ensure that too much torque is not applied to the screws or the scope ring. It causes damage to the threads of the screws and an unreliable fit.

- Instead of a thread locker, using a torque wrench to mount with the perfect torque values can help the scope to work fine during the whole shooting experience.

2. Blue Thread Locker for the Bases

It is recommended to use a blue thread locker on expensive scope base screws that attach to the new rifle, as they are unlikely to ever be removed.

For steel receivers, use a maximum torque of 25 inch-lb and for aluminum receivers, use a maximum torque of 15 inch-lb, as per the manufacturer’s specifications.

Warning: Red thread locker should never be used on the base or rings, as it can make it difficult to remove the screws.

Torquing Scope Rings on Scope Mounts

Torquing scope rings is a necessary step to ensure your scope is mounted securely and will remain properly aligned.

When correctly torqued, scope rings provide a guarantee that your scope won’t move or lose its zero, so you can enjoy precise shooting results with every pull of the trigger.

Step 1: Making the Firearm Secure

Confirm the firearm is empty and secure it in a rifle rest.

Step 2: Tightening the Scope Ring

Use the L-shaped hex key that comes with most scope rings to tighten the ring screws on the cap (if there are more than two screws, do so in a crisscross pattern) gradually until they are snug.

Attention: Ensure that your scope can still move around but isn't loose. This is when you adjust the scope to get the right eye relief and make sure it is level.

Step 3: Setting the Torque

Use a gunsmithing torque wrench (auto mechanic torque wrenches with the appropriate size hex socket can be used with care) and set the torque to 10 inches/lbs. It is crucial to use inch/lbs and not foot-pounds and to tighten dry threads (no Loctite or thread locker).

Attention: After tightening all ring screws to 10 inches/lbs using a criss-cross pattern with each ring, torque to the scope manufacturer's specifications.

Do You Need Torque Drivers to Mount a Scope

To secure a scope, it is recommended to use a wrench to mount a scope and ensure that the screws are tightened to the correct amount of force. It can be a helpful tool for achieving the correct torque, as it allows the user to accurately adjust the amount of force applied when mounting the scope.

Additionally, using a torque driver eliminates the guesswork involved in manually torquing the screws and ensures that the scope is properly mounted.

How To Tighten the Scope Mounting Screws without Rotating the Scope

When tightening the scope mount screw, it is important to ensure that the scope is not rotated as this can cause misalignment.

- One way to do this is by holding the scope in place with one hand while using a torque wrench to tighten the screws with the other.

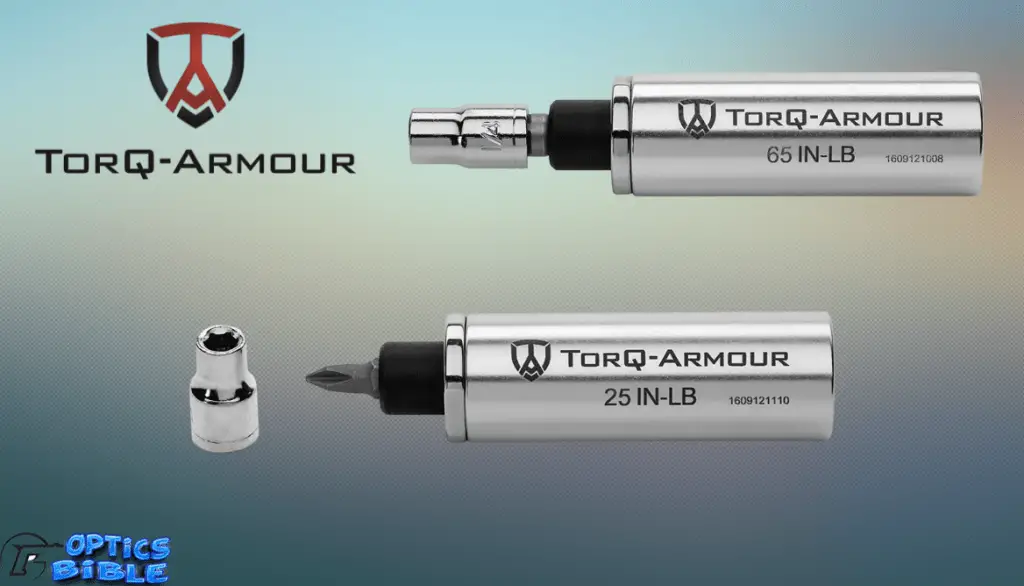

- Use a torque-limiting bit, such as the TorQ-Armour Miniature Torque Limiter Socket, which will stop applying torque when it reaches a specific level and prevent the scope from rotating.

- Finally, using a torque wrench handle with a ratchet mechanism, allows you to rotate the handle without rotating the scope.

Best Torque Wrenches for Mounting Rifle Scopes

Finding the best torque wrench for scope mounts requires researching different models and choosing one that fits your needs and budget.

Options to consider include the Capri Tools CP21075 Certified Limiting Torque Driver Set, the Fix It Sticks All-in-One Torque Driver Kit, the Wheeler Firearms Accurizing Torque Wrench, and the Weaver Gunsmithing Torque Wrench for Scopes.

Why you Should Use a Torque Wrench?

It is essential for accurate and safely tight or loose scope screws. It prevents over-torquing, protects your equipment, and reduces wear on screws. It also prevents the scope from becoming misaligned or losing its zero point.

Best Torque Wrenches – Our Top Pick

When selecting a torque wrench, it is important to consider:

- The size of the screws you will be using, the torque accuracy needed, and the type of application.

- If you are looking for a general-purpose one, then a simple adjustable wrench or socket set should suffice.

- If you need more precision and accuracy then consider a digital type with adjustable torque settings.

- It is also good to check the manufacturer’s recommendations as they can provide specific torque requirements for the particular application. Read below!

1. Capri Tools CP21075 Certified Limiting Torque Driver Set

Model Number: | CP21075 |

Torque Range: | 10 – 50 inch-lbs |

Torque Accuracy: | +/- 6% |

Torque Increments: | 1 in/lbs |

Manual or Digital: | Manual |

Standards Met: | ASME B107.300-2010 and ISO 6789 |

Used for: | Electrical, Automotive, Aerospace, and Manufacturing work |

The Capri Tools CP21075 is an excellent tool to help you achieve precise torque specifications. This set comes with 8 adapters and a storage case, making it a perfect choice for anyone looking for an easy-to-use and quality set.

- Features a built-in torque limiter to prevent overtightening of fasteners.

- Comes with 8 adapters and a storage case.

- Features a digital LCD

- Cannot be used as a drill like its latest models (e.g. CP26000-50).

2. Fix It Sticks All-in-One Torque Driver Kit

Model Number: | rtgfh-1 |

Torque Range: | 15 – 65 inch-lbs |

Torque Accuracy: | +/- 10% |

Torque Increments: | 1 in/lbs |

Manual or Digital: | Manual |

Standards Met: | ANSI B107.14m |

Used for: | To tighten the screw or bolt |

The Fix It Sticks All-in-One Torque Driver Kit offers precision torque for a variety of applications. This kit features interchangeable bits, a torque indicator, and adjustable torque dials for precise operation.

- Interchangeable bits for a variety of uses.

- Features a torque indicator and adjustable torque dials.

- Easy to use and accurately displays torque readings.

- Low torque range, compared to most torque wrenches.

3. Vortex Optics Torque Wrench Scope Mounting Kit

Model Number: | CTW2 |

Torque Range: | 10-50 inch-lbs |

Torque Accuracy: | +/- 4% |

Torque Increments: | 1 in/lbs |

Manual or Digital: | Digital |

Standards Met: | ANSI B107.14m |

Used for: | Fastening and tightening of scope rings, base screws, and guard screws |

It is an ideal accessory for mounting and dismounting rifle scopes safely and securely. This kit has all the necessary tools and equipment to ensure that your scope is correctly torqued to the recommended specifications.

- Easy to use with adjustable torque settings and audible clicks.

- Constructed with anodized aluminum and stainless steel components.

- Features a digital LCD.

- Comes with all the necessary tools and equipment for mounting scopes.

- Not portable, limited to workbench use.

4. KAIFNT K551 Digital Torque Screwdriver/Wrench Set

Model Number: | K551-85 |

Torque Range: | 5-85 inch-lbs |

Torque Accuracy: | +/- 2% |

Torque Increments: | 0.2 in-lbs |

Manual or Digital: | Digital |

Standards Met: | ANSI B107.14m |

Used for: | Fastening and tightening of the screw or bolt |

The KAIFNT K551 Digital Torque Screwdriver/Wrench Set is a reliable tool that offers precise torque control. This set features an LCD digital display, interchangeable bits, and adjustable torque settings for a wide range of applications.

- Comes with an auto-calibration and auto shut-off function for safe use.

- The ergonomically designed handle provides a comfortable grip.

- Features an LCD digital display and interchangeable bits.

- The compact design makes it easy to store.

- Not suitable for large-scale applications

5. Wheeler Firearms Accurizing Torque Wrench

Model Number: | 553556 |

Torque Range: | 10-65 inch-lbs |

Torque Accuracy: | +/- 5% |

Torque Increments: | 0.25 in-lbs |

Manual or Digital: | Manual |

Standards Met: | ANSI B107.14m |

Used for: | Fastening and tightening the screw and bolt |

The Wheeler Firearms Accurizing Torque Wrench is an essential tool for all gunsmiths looking to achieve professional results. It is adjustable, accurate, and easy to use, with a range of 10-65 inch lbs of torque.

- Features a comfortable rubber-coated grip for improved handling.

- Comes with 9 bits for different firearms and applications.

- Easy to use, with an adjustable torque dial.

- Durable construction, made from steel and aluminum.

- Manual operation with predefined settings.

6. Weaver Gunsmithing Torque Wrench for Scopes

Model Number: | WEAV849728 |

Torque Range: | 10-65 inch-lbs |

Torque Accuracy: | +/- 4% |

Torque Increments: | 0.25 in-lbs |

Manual or Digital: | Manual |

Standards Met: | ANSI B107.14m |

Used for: | To tighten the screws of rifle scopes |

The Weaver Gunsmithing Torque Wrench for Scopes is the perfect tool for any gunsmith in need of accurate and adjustable torque delivery. It features a micro-adjustable dial, a dual-drive head, and a built-in bubble level, making it an ideal tool for mounting and dismounting scopes quickly and safely.

- The dual-drive head allows for two bits at once.

- Easy to use, with an adjustable torque dial.

- Features a built-in bubble level for precise alignment.

- Durable construction, made from steel and aluminum.

- Compact design for easy storage.

- Manual operation with set torque specifications.

7. TorQ-Armour Miniature Torque Limiter Socket

Model Number: | TW-112 |

Torque Range: | 65 inch-lbs |

Torque Accuracy: | +/- 6% |

Torque Increments: | 1 in-lbs |

Manual or Digital: | Digital |

Standards Met: | ANSI B107.14m |

Used for: | To fasten and tighten the screw and bolt |

The TorQ-Armour Miniature Torque Limiter Socket is designed to provide reliable and precision torque limiting. This socket features a compact size, an adjustable torque control, and an LED torque indicator, making it an ideal choice for those who need precision torque control.

- One-way ratchet system that prevents overtightening.

- Features an LED torque indicator and interchangeable bits.

- The compact size allows for easy portability.

- Digital operation with adjustable torque settings.

- More expensive than analog torque sockets.

How Does a Rifle Scope Torque Wrench Work?

A rifle scope torque wrench works by allowing the user to adjust the amount of force they apply when you tighten or loosen the screws on the scope. The wrench is typically equipped with a scale that indicates the amount of torque that has been applied.

Here are the steps to use it on a rifle scope:

- Attach the appropriate bit and socket to the torque wrench.

- Set the torque to the recommended value indicated by the manufacturer.

- Securely tighten or loosen the scope base without over-torquing.

- Check the torque setting after each screw is tightened or loosened.

- Repeat the process until all screws are tightened or loosened to the correct torque setting.

NEVER Leave your Torque Wrench on High Setting Torque Values

It is important to never leave it in high settings, as this can lead to a variety of issues. Over-torquing scope base screws can cause damage to the scope, the mounting base, and the rifle. Read below for more critical reasons for never leaving the wrench on a high setting!

- Over-torquing can result in the small screws stripping or breaking, causing the scope to become loose and misaligned.

- High torque values settings may cause damage to the scope’s internal components.

- It can increase the possibility of cross-threading screws.

- Increased torque values setting can cause the mounting base to be too tight, leading to an uncomfortable shooting experience.

- Torque settings can lead to increased wear and tear on the scope and the rifle.

- High torque settings can cause the scope to lose its zero, making it difficult to accurately aim.

Verdict – Best Among All

All the above-mentioned tools are amazing but there has to be one winner among all the choices. The best choice among these options is the Vortex Optics Torque Wrench Scope Mounting Kit.

This kit comes with a wide range of torque settings and an ergonomic handle for easy use, making it ideal for all scope mounting applications. It includes all the necessary tools and accessories such as a screwdriver bit set, scope rings, scope clamp, and a storage case, making it a comprehensive solution for any scope mounting needs.

Can You Mount a Scope without a Torque Wrench – FAQ

What can I use instead of a torque wrench?

You can use a socket wrench, ratchet wrench, or adjustable wrench. These wrenches can provide leverage to loosen or tighten nuts and bolts.

How important is torquing scope rings?

Torquing scope rings is very important. It ensures that your scope is securely mounted and does not move around when firing a rifle. Properly torqued scope ring screws also ensure that the scope will hold its zero after many rounds of firing.

How much torque is needed to mount a scope?

The torque needed to mount a scope varies depending on the type of scope, mounting system, and firearm you are using. A general rule of thumb is to use 17-20 inch lbs of torque.

How much torque can you apply by hand?

Generally, you can apply up to 15-20 inch lbs of torque by hand. It’s best to use a wrench to ensure that you are applying the proper amount of torque for your new scope mounts.

What happens if you don’t torque bolts?

If you do not torque the bolts correctly, it could cause the scope to move around, change its zero point, and even become damaged.

Are torque bolts necessary?

Yes, a torque bolt is necessary to ensure that your scope is secured properly and that it will not move or change its zero point over time.

Conclusion

It is highly recommended to use a suitable wrench when mounting a scope to ensure that the screws are tightened to the correct specification. Doing so will enable you to mount the scope securely, accurately align it with your firearm, and keep it from shifting or loosening over time.

Have you ever tried mounting a scope without a torque wrench? If yes, how did you do it, and did this method damage the scope? Share your opinion in the comments! We would love to know about your choice.